I remember feeling unsure about assembling my first pneumatic sit-stand desk. The instructions looked clear. I grabbed a screwdriver and started. With patience, I found the process simple. Anyone can put together the best pneumatic sit stand desk or even a pneumatic adjustable sit stand desk at home.

Key Takeaways

- Gather basic tools like hex keys and a screwdriver, prepare a clean workspace, and organize all parts before starting assembly.

- Follow the step-by-step instructions carefully to build the frame, attach the desktop, and install the pneumatic mechanism safely.

- Check stability and safety by tightening screws, adjusting height, and performing regular maintenance to keep the desk working smoothly.

What You Need for Assembling a Pneumatic Sit-Stand Desk

Essential Tools and Supplies

When I started assembling my pneumatic sit-stand desk, I gathered the tools I needed first. Most desks come with the basics, but I found these tools essential:

- Hex keys (Allen wrenches) for tightening screws and bolts.

- Phillips head screwdriver for attaching the desktop.

- Power drill if the desktop does not have pre-drilled holes.

I did not need any special tools. The instructions made it clear that hex keys and a screwdriver or drill would handle almost every step.

Setting Up Your Workspace

Before I began, I prepared my workspace to keep everything safe and organized. I made sure the area was clean and free of clutter. I wore gloves to protect my hands and sturdy shoes to protect my feet. I used proper lifting techniques when moving heavy parts. I also checked that my work surface was flat and stable. To avoid static electricity, I used a mat and wore a wrist strap. I kept the room at a comfortable humidity level. I arranged my chair and desk so I could work without straining my back or neck. I placed all parts within easy reach.

Tip: Take regular breaks and stretch your arms and legs to stay comfortable during assembly.

Skills and Preparation

I did not need advanced skills to assemble my desk. I measured the space to make sure the desk would fit. I organized all the parts before starting. I followed each step in the manual, using my screwdriver and hex keys. I attached the frame, secured the pneumatic mechanism, and fixed the desktop. I adjusted the height to match my sitting and standing positions. I used cable ties to keep wires tidy. The process felt simple because pneumatic sit-stand desks do not require electrical work. Basic hand tool skills and careful attention to instructions helped me finish the job safely.

Step-by-Step Assembly of a Pneumatic Sit-Stand Desk

Unboxing and Organizing Desk Parts

I always start by opening the box carefully. I lay out all the parts on a clean surface. I check the instruction manual and match each part to the list. This helps me spot missing or damaged pieces before I begin. I group similar items together, like screws, bolts, and frame pieces. I keep small hardware in a bowl or tray so nothing rolls away. I find that organizing everything first saves time and prevents mistakes later.

Tip: Take photos of the parts layout. This makes it easier to remember where each piece goes if you need to pause and return later.

Building the Frame

I begin with the frame because it forms the base of the pneumatic sit-stand desk. I follow the manual step by step. I connect the legs and crossbars, making sure each bolt is tight but not over-tightened. I use the provided hex keys and my screwdriver. I double-check that the frame sits flat on the floor. If the frame wobbles, I adjust the feet or move it to a more level spot. A sturdy frame keeps the desk stable during use.

Attaching the Desktop

Attaching the desktop is a key step. I place the desktop upside down on a soft surface to avoid scratches. I align the frame with the pre-drilled holes. I use wood screws to secure the frame to the desktop. Screws give a strong and lasting hold. Sometimes, I use dowels or biscuits to help line up the frame and desktop, especially with wood. If the manual suggests, I add a small amount of adhesive and clamp the pieces together for extra strength. I always check that the desktop sits evenly on the frame before tightening everything.

- Screws provide solid reinforcement and keep the desktop from shifting.

- Dowels or biscuits help with alignment and prevent movement over time.

- Adhesives can add strength if used with pressure and clamps.

- Wood screws are simple and durable for attaching table tops to legs.

Installing the Pneumatic Mechanism

I handle the pneumatic mechanism with care. I know it uses gas-filled cylinders to help lift the desk smoothly. I follow the instructions to attach the mechanism to the frame and desktop. I make sure the load is balanced across the desk surface. Uneven weight can cause the desk to tilt or the mechanism to work harder. I check the desk’s weight capacity and keep the load within the ideal range, usually 30-50 pounds. If I add too much weight, I notice the adjustment becomes harder and I need to help lift or lower the desk. I pay attention to stability, especially since pneumatic desks do not have electronic safety features. I always make sure the desk stands firm before testing the height adjustment.

Note: Manual pneumatic desks rely on mechanical parts. I stay alert and avoid sudden movements to prevent accidents.

Final Adjustments and Safety Checks

I finish by making sure the desk operates smoothly. I test the counterbalance mechanism to see if the desk lifts and lowers with little effort. I check for brakes or locking handles that keep the desk at the right height. I adjust the torque if the manual allows, so the lifting force matches my needs. I look for sliding limit rods or nested frames that stop the desk from wobbling. I make sure gas struts control the speed of lowering, so the desktop does not drop suddenly. I lock the desk at my preferred height and make sure the handle is easy to reach.

After these adjustments, I perform safety checks:

- I tighten all screws and bolts.

- I set the desk at a safe height, not too high.

- I use a level to check the desktop.

- I adjust foot levelers if the desk wobbles.

- I inspect for loose cables or anything that could affect stability.

Safety Tip: I check the desk regularly to make sure it stays stable and secure, especially after moving or adjusting it.

Tips, Troubleshooting, and Getting Help with Your Pneumatic Sit-Stand Desk

Safety Tips for Assembly

I always put safety first when I assemble a pneumatic sit-stand desk. I wear gloves to protect my hands from sharp edges. I lift heavy parts with my legs, not my back, to avoid injury. I keep my workspace clear so I do not trip over tools or parts. I make sure the desk sits on a flat surface before I start. I never rush the process. Taking my time helps me avoid mistakes and accidents.

Common Mistakes to Avoid

I learned that skipping steps in the manual can cause problems later. I double-check each screw and bolt. If I do not tighten them enough, the desk may wobble. I also avoid forcing parts together. If something does not fit, I check the instructions again. I make sure I do not overload the desk with heavy items, which can damage the pneumatic mechanism.

Troubleshooting Assembly Problems

Sometimes, my desk wobbles or does not move smoothly. I check for loose screws and tighten them. I make sure the legs are even and the desk sits flat. If the desk still feels unstable, I use foot levelers. I remove anything that blocks the desk’s movement. Regularly tightening bolts every six months keeps the desk steady. Pneumatic sit-stand desks use a gas cylinder, so smooth movement depends on balanced pressure and secure parts.

When to Seek Professional Assistance

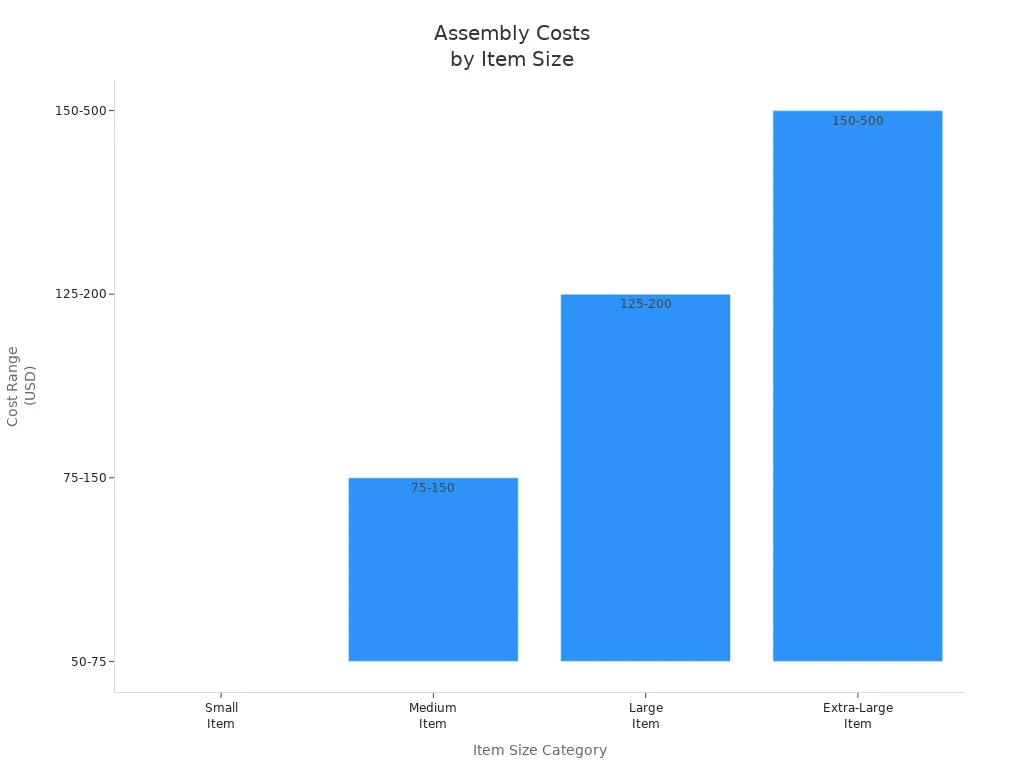

Some desks are heavy or oversized. I ask for help if I cannot lift the parts safely. Professional assembly services can handle large desks and tricky setups. These services usually cost between $200 and $600, depending on desk size and complexity. Hourly rates average about $90. Here is a chart showing typical assembly costs:

Tip: If I feel unsure or the desk seems too complex, I call a certified assembler for help.

I found assembling a pneumatic sit-stand desk easy and rewarding. I followed each step and took my time. Over the years, I noticed these benefits:

- I moved more and felt less tired.

- My posture improved and neck pain decreased.

- Quick adjustments kept me focused and healthy.

FAQ

How long did it take me to assemble my pneumatic sit-stand desk?

I finished assembly in about one hour. I followed the manual step by step. I took short breaks to stay focused.

Did I need help lifting any parts during assembly?

I lifted most parts by myself. For the desktop, I asked a friend to help. Heavy pieces can be tricky to move alone.

What should I do if a part is missing from the box?

I contact the manufacturer right away. I provide my order details and photos. Most companies send replacement parts quickly.

Post time: Aug-19-2025